Sewage Treatment Plant

Essential for managing water discharged from homes, businesses, hospitals, institutions, communities, and industries.

What is a Sewage Treatment Plant?

Sewage Treatment Plant to manage water discharged from homes, businesses, hospitals, Institutions, communities and industries to reduce the threat of water pollution.

Sewage treatment plants collect, treat, and discharge wastewater, providing a service essential to environmental and public health. Without adequate treatment, sewage will leach into the environment and contaminate ecosystems. For example, sewage contains bacteria and chemicals that break down using oxygen in the water. In doing so, they use oxygen that fish and aquatic life needs to survive, so it needs treatment to preserve the ecosystem.

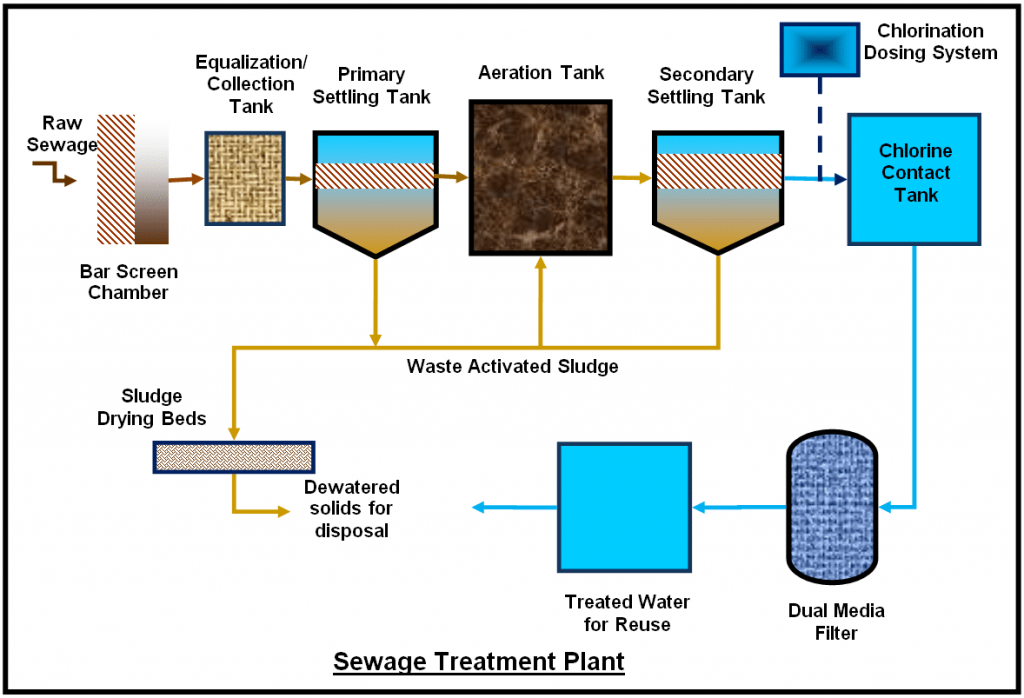

How does a sewage treatment plant work?

Sewage treatment plants run wastewater through multiple treatment stages. After preliminary filtration, there are three main stages of wastewater treatment (primary, secondary, and tertiary), with the third stage reserved for polishing.

Prefabricated STP Solutions & Turnkey Sewage Treatment Projects

Nirmla Water has a choice of various sizes of Prefabricated Modular Sewage Treatment Plants & turnkey projects and process engineering expertise on large Sewage Treatment Plants. Various innovative technologies are involved in construction of these plants like as.

1. Up-flow Anaerobic Sludge Blanket Reactor (UASBR)

2. Activated Sludge Process (ASP)

3. Moving Bio Bed Reactor (MBBR)

4.Membrane Bio Reactor (MBR)

5. Electro Coagulation/Direct Current Ionizer (EC/DCI)

6. Sequential Bio Reactor (SBR)

Prefabricated Sewage treatment Plant Based on Electro Coagulation/Direct Current Ionizer (EC/DCI) Technology

Electrocoagulation is an electrochemical water and waste water treatment that uses an electrochemical cell in which a direct current voltage is applied to a sacrificial electrode, usually iron or aluminum to treat water/waste water before re-use or can be released into the environment.

Trunkey Project of Sewage treatment Plant Based on SBR Technology

The sequencing batch reactor (SBR) is a fill-and draw activated sludge system for wastewater treatment. In this system, wastewater is added to a single “batch” reactor, treated to remove undesirable components, and then discharged. Equalization, aeration, and clarification can all be achieved using a single batch reactor. To optimize the performance of the system, two or more batch reactors are used in a predetermined sequence of operations. SBR systems have been successfully used to treat both municipal and industrial wastewater. They are uniquely suited for wastewater treatment applications characterized by low or intermittent flow conditions.

Trunkey Project of Sewage treatment Plant Based on MBBR Technology

Moving bed biofilm reactor (MBBR) is a biological wastewater treatment process that uses plastic carriers covered in biofilm to break down organic waste. MBBR systems are compact, simple, and low maintenance, and can be used in a variety of industries. They are ideal for installations where space is limited, and can withstand peak loads and flow variations.

MBBR has several advantages, including:

• Space constraints

MBBR is known for its small footprint, which can free up space for other machinery and systems.

• Shock loads

MBBR can resist shock loads and other drastic changes, such as temporary spikes in pH levels.

• Efficiency

MBBR works quickly, achieving a relatively low hydraulic retention time (HRT).

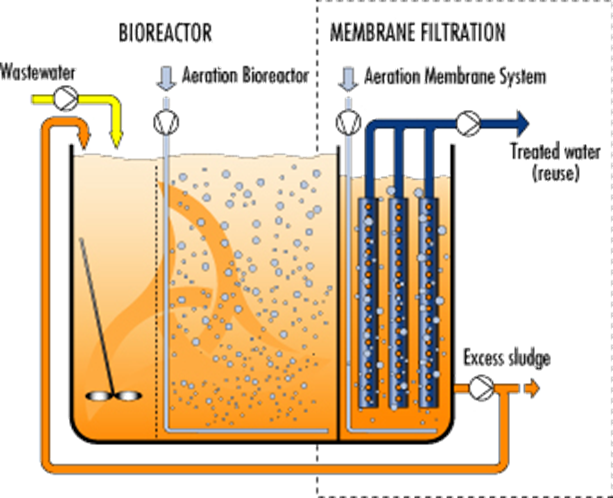

Membrane BioReactor (MBR)

A Membrane BioReactor (MBR) is a process which combines a microfiltration or ultrafiltration membrane unit with a suspended growth bioreactor, and is now widely used in both municipal and industrial WasteWater Treatment Plants (WWTPs).

FAQ's

Frequently ask question

Nirmla Waters provides a comprehensive range of water treatment solutions, including water purification systems , wastewater treatment plants, industrial water treatment , community water treatment plants, environmental management services.

Yes, Nirmla Waters offers tailored and customized water treatment solutions to meet the unique requirements of households, communities, and industries. Our team conducts thorough assessments and feasibility studies to design specialized systems that address your specific needs.

Absolutely. Nirmla Waters provides end-to-end, turnkey project execution, handling everything from design and engineering to procurement, installation, and commissioning of water treatment plants and systems.

Environmental stewardship is a core value at Nirmla Waters. Our solutions are designed to minimize water wastage, promote water conservation, and reduce the carbon footprint associated with water treatment processes.

Nirmla Waters serves a diverse range of industries, including but not limited to pharmaceuticals, power generation, food and beverage, electronics, and manufacturing.

Yes, Nirmla Waters provides after-sales support and maintenance services.

Exceptional Water Treatment, at Your Service

Reliable Water Treatment Expertise. Contact Us for Residential, Industrial, or Community Solutions.

Send us an email

info@nirmlawater.com

Give us a call

+91 94787 22835

Drop us a line

You can easily reach out to Nirmla Waters for your water treatment needs, inquiries, or to request a consultation or quote.